We take up cleaning of crude oil tanks of all capacities up to utmost

satisfaction level of our esteemed clients. Crude oil tank bottoms are

typically high in hydrocarbons,it is a valuable raw material which can

be recovered and recycled back to the refining process. When crude

tanks are cleaned, first, the sludge is removed from tank bottom and

simultaneously the oil is recovered from it.

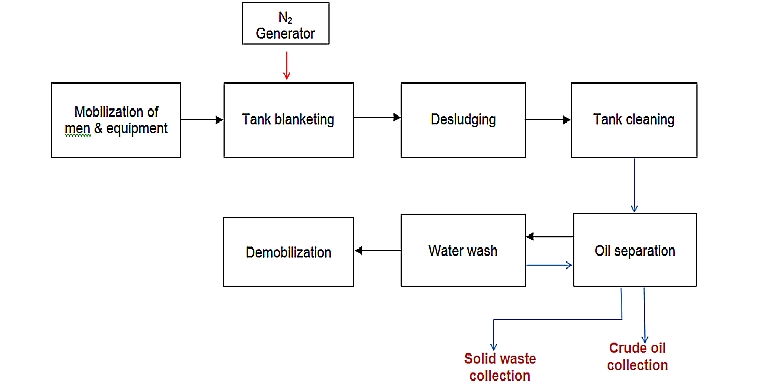

To ensure a safe tank cleaning process, an inert gas typically nitrogen

is injected into the tank for blanketing.The purpose of inert gas introduction

is to reduce the oxygen level below 8% to eliminate the risk of explosion

which may cause due to static electric effect and the inert condition is

maintained for entire cleaning process.

Desludging is the first process in the cleaning of the tank and this is where most of the oily sludge from the tank is removed. The desluding process may begin only when the oxygen level has fallen below 8% in the tank.

The tank cleaning process consists of an oil wash and if required a final hot water wash. Efficient and especially designed nozzles are installed on the roof of the tank which are used to liquefy the sludge at the bottom of the crude oil tank and thus play a vital role in the cleaning process. The nozzles can be programmed to focus on areas that require more intensive desludging/cleaning. The sludge – oil mixture then being pumped out to filtration unit for separation of oil and sludge. There are three tank cleaning methods widely used for crude tank cleaning namely; manual, semi auto and no men entry.

Process Flow Diagram